Precision Optical Mold Development

Igiant Optics specializes in the design and manufacturing of high-precision optical molds. Our capabilities include mold flow analysis, CNC precision machining, and trial mold validation. We are equipped with advanced machinery such as high-precision EDM and WEDM systems. Our wire-cutting accuracy reaches ±0.001mm, with a minimum wire diameter of Ø0.05mm. Integrated with automated optical measurement and 3D scanning systems, we ensure outstanding mold accuracy and molding quality.

Automated High-Volume Production

Igiant Optics has introduced fully electric injection molding machines from Japan, combined with automated material feeding and cutting systems to achieve efficient and stable mass production. This highly automated process ensures product accuracy and consistency, significantly improving productivity. Our monthly injection capacity can reach up to 100 million pieces.

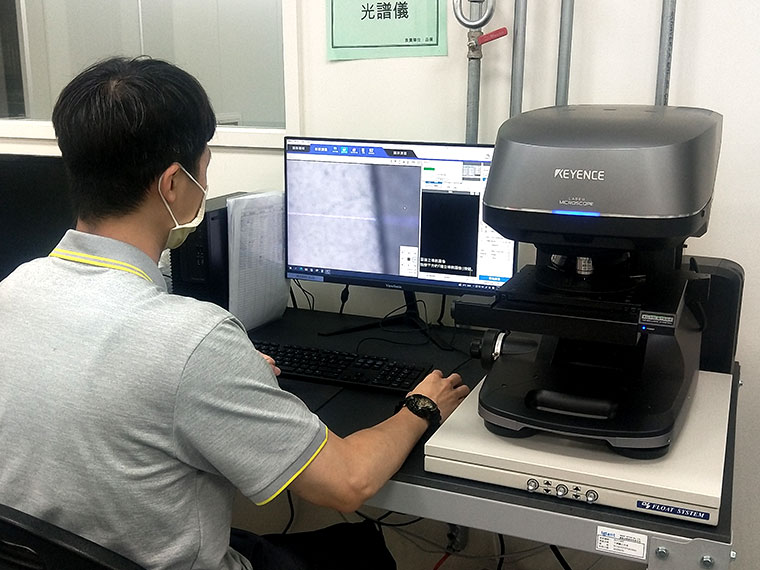

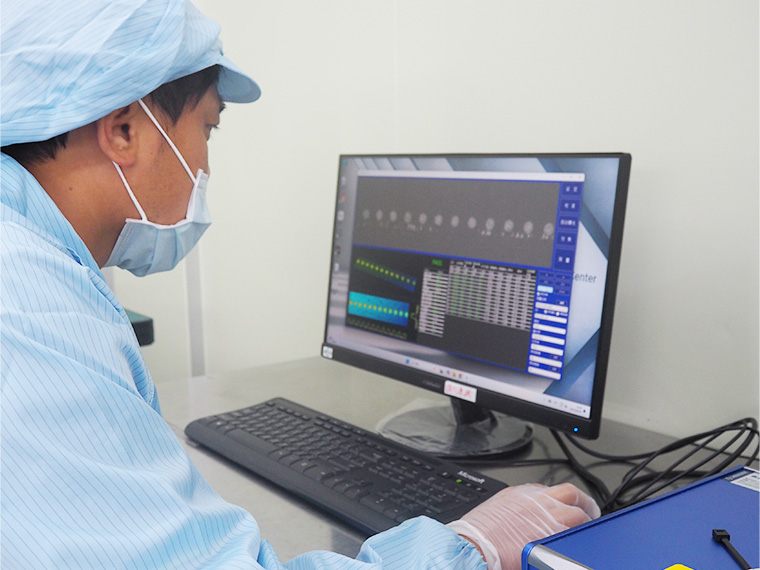

High-Precision Component Inspection and Quality Control

Quality control is a top priority at Igiant Optics. We utilize Automatic Visual Inspection (AVI) systems and dimensional measurement tools to guarantee the precision and quality of every product. Production takes place in a cleanroom environment to prevent contamination and maintain the highest quality standards. We also offer highly customized inspection services tailored to customer requirements.

Optical-Grade Cleanroom Environment

giant Optics was certified with ISO 9001 and ISO 14001, and our cleanroom meets ISO 14644-1 Class 1K standards. We are committed to providing high-quality, highly reliable optical products. All production and quality control processes are aligned with international standards, establishing a comprehensive quality assurance system to meet the stringent demands of global customers.

Core Components for Optical Communication Connectors

Igiant Optics actively engages in the optical communication industry, focusing on the manufacturing of high-precision optical components, including key technologies for high-speed communication modules and connector coupling. Our products include Ferrules, MPO Patchcords, Pig Tails, Jumpers, and Lens Arrays, etc. We support customers in accelerating product development, improving yield, and ensuring consistency. With the growing demand for high-speed, high-bandwidth transmission driven by AI computing and data centers, CPO technology is becoming a mainstream architecture. Igiant has developed 12 fiber and 16 fiber MT Ferrules with low insertion loss and high dimensional precision, supporting both single-mode and multi-mode fiber applications. Customizable options are available for 24 fiber, 48 fiber, and other high-density configurations to meet the evolving needs of next-generation optoelectronic systems.

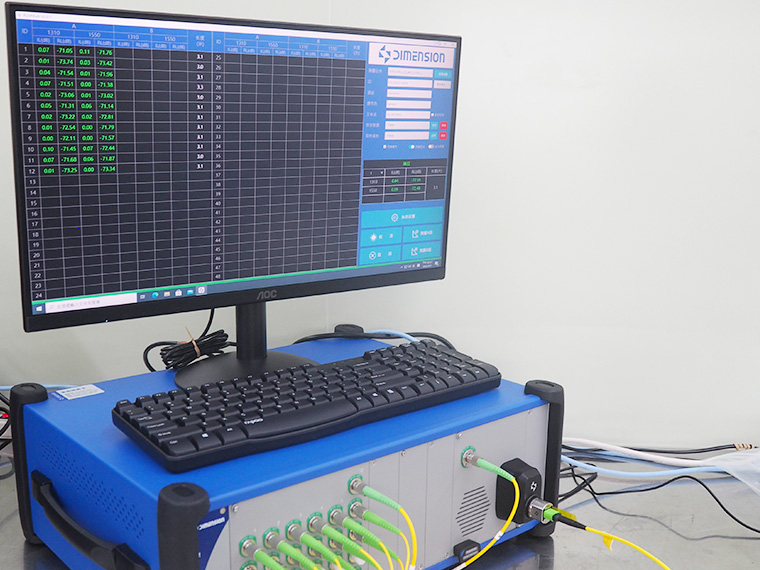

Advanced Optical Communication Testing Capabilities

Igiant Optics has established a comprehensive testing and quality assurance system for optical communication products, covering incoming material inspection, precise end-face geometry measurement, and final optical performance evaluation. We provide testing services for high-speed signal integrity, optical coupling efficiency, and communication quality analysis. We also ensure product compliance with IEC, TIA, and Telcordia (GR-326) international standards, regardless of fiber type or connector format. By enforcing rigorous quality control throughout the manufacturing process, we deliver products that meet the high-performance standards expected by global customers—demonstrating our commitment to quality and technical excellence.