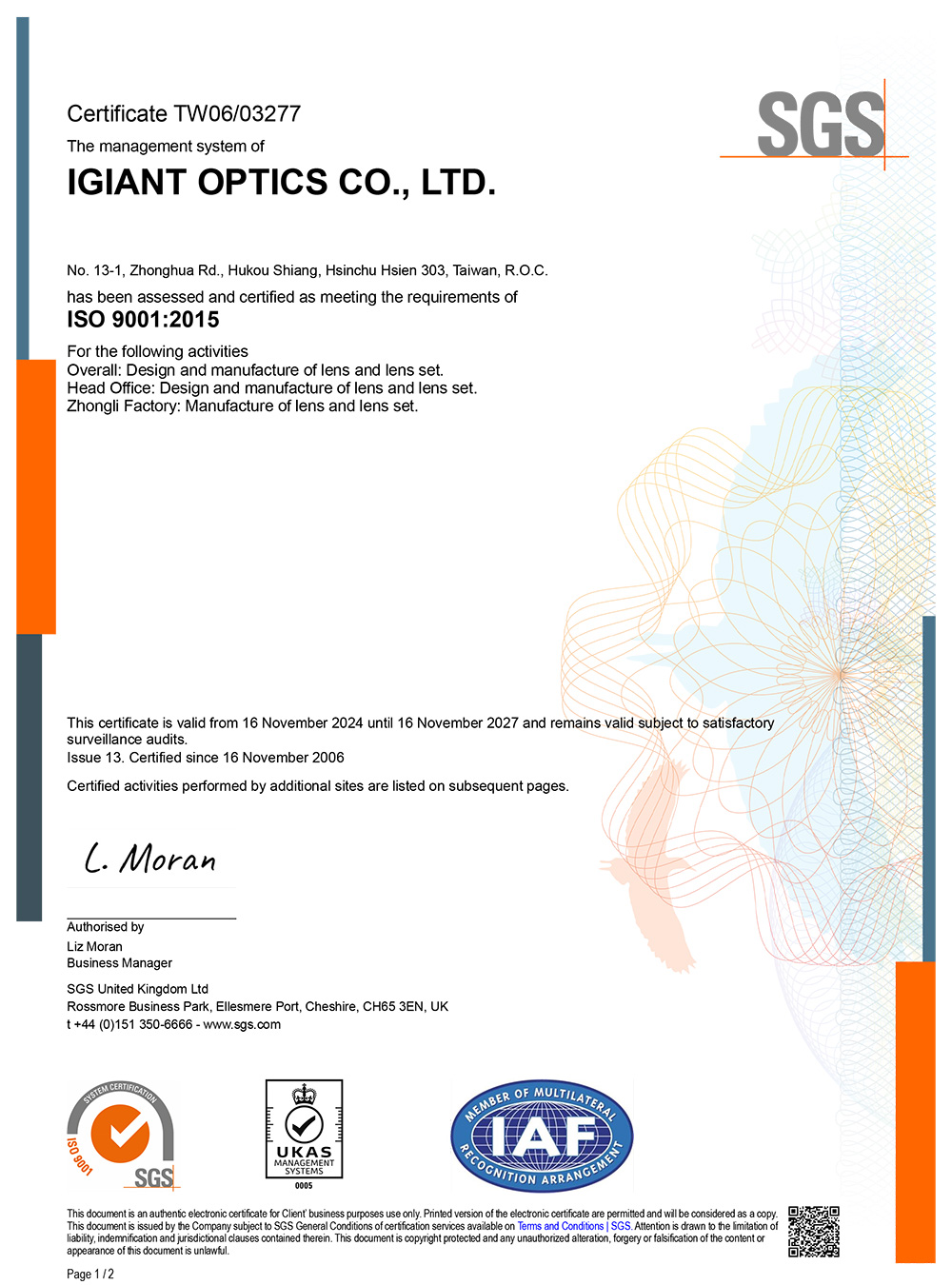

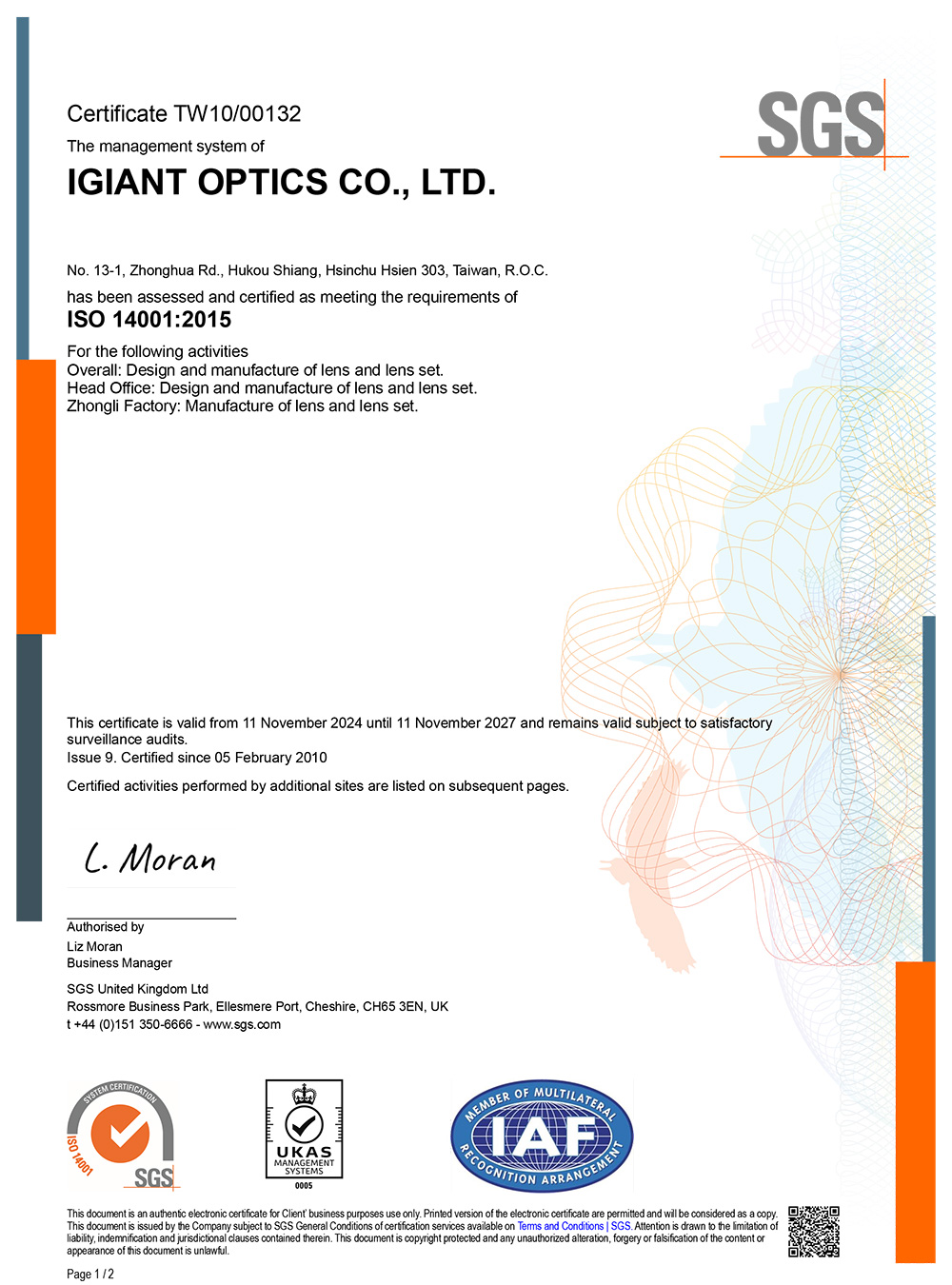

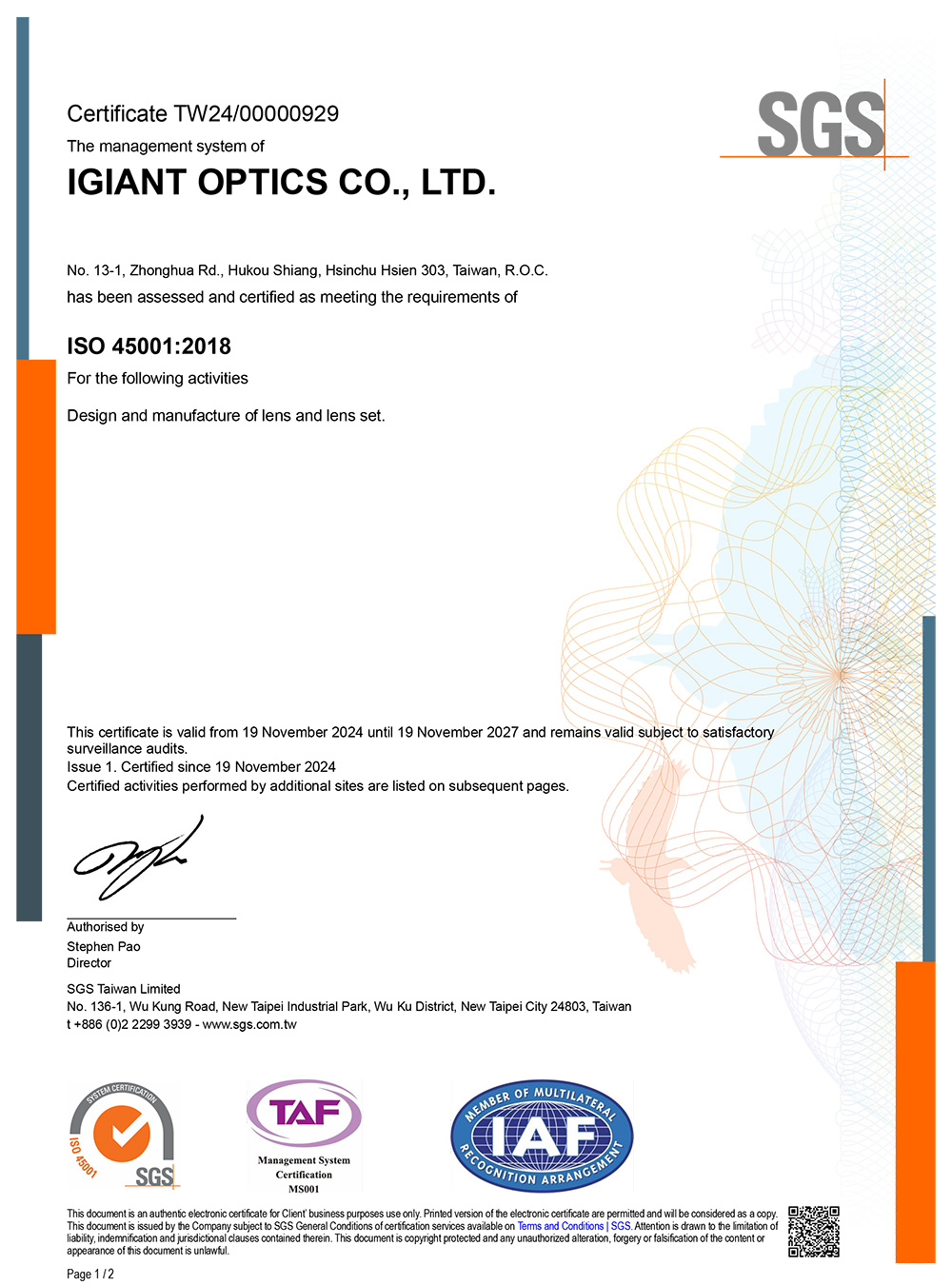

Quality / Environmental / Occupational Health and Safety Certifications

ISO 9001、ISO 14001、ISO 45001

Quality policy

Total Quality Assurance, Excellent Management, Customer Satisfaction.

Environmental policy

Full participation, care the earth, comply with laws and regulations, pollution prevention, continuous improvement.

Establish a good communication channel, and comply with the commitment to the stakeholders.

Occupational Health and Safety Policy

Comply with legal and regulatory requirements, establish a healthy and safe working environment,provide training and promote health and safety knowledge, and continuously improve health and safety management.